| Icon

|

Name

|

Topic

|

Description

|

Author

|

Code

|

|

|

![]()

|

ArchTextures

|

Architecture and construction

|

It allows you to add basic, non-photorealistic textures to architectural objects created with the Arch Workbench.

|

furti

|

https://github.com/furti/FreeCAD-ArchTextures

|

![]()

|

![]()

|

BCFPlugin

|

Architecture and construction

|

It aims to support the BIM Collaboration Format (BCF).

|

podestplatz

|

https://github.com/podestplatz/BCF-Plugin-FreeCAD

|

![]()

|

|

![]()

|

BIM

|

Architecture and construction

|

It aims to implement a complete building information modeling (BIM) workflow in FreeCAD.

It extends the Arch Workbench, and gathers tools from other workbenches to provide an environment that is convenient to model buildings, and work with IFC files.

|

yorikvanhavre

|

https://github.com/yorikvanhavre/BIM_Workbench

|

![]()

|

|

![]()

|

BIMBots

|

Architecture and construction

|

It allows you to upload a FreeCAD model or selected parts of a FreeCAD model to a BIMBots instance (usually a BIMServer with external services enabled), and perform different services and analyses on your model, and read the results in FreeCAD, usually under the form of a text report, or a BCF file.

|

BIMBots

|

https://github.com/opensourceBIM/BIMbots-FreeCAD

|

![]()

|

|

![]()

|

Dodo

|

Architecture and construction

|

It provides tools to create frames (trusses, beams) and pipelines (tubes, elbows, flanges), and query those objects.

This is the new version of Flamingo, intended for Python 3 and Qt5.

|

oddtopus

|

https://github.com/oddtopus/dodo

|

![]()

|

|

![]()

|

Flamingo

|

Architecture and construction

|

It provides tools to create frames (trusses, beams) and pipelines (tubes, elbows, flanges), and query those objects.

This is the old version of Dodo, intended for Python 2 and Qt4.

You should prefer Dodo for new models.

|

oddtopus

|

https://github.com/oddtopus/flamingo

|

![]()

|

![]()

|

|

|

GeoData

|

Architecture and construction

|

It provides tool to import geographical information from a given point on Earth by its latitude and longitude, of from OpenStreetMap, Google Maps, Bing Map, or Here Map.

|

microelly2

|

https://github.com/microelly2/geodata

|

|

![]()

|

![]()

|

Geomatics

|

Architecture and construction

|

It is partially based on the GeoData.

It provides functionality specific to Geomatics or Survey engineering, including importing point files, creating surfaces, creating contours, and creating sections.

This is partially migrated to the Trails workbench.

|

HakanSeven12

|

https://github.com/HakanSeven12/FreeCAD-Geomatics-Workbench

|

![]()

|

![]()

|

![]()

|

OSE Piping

|

Architecture and construction

|

Create different piping fittings.

It supports Flamingo.

|

Ruslan

|

https://github.com/rkrenzler/ose-piping-workbench

|

![]()

|

|

![]()

|

Reinforcement

|

Architecture and construction

|

It provides tools for Reinforcement Generation and Detailing.

This workbench provides an interface and presets for the creation of common rebar types.

And tools to generate rebars bill of material, rebar shape cut list, bar bending schedule, and rebars drawing and dimension.

|

amrit3701

|

https://github.com/amrit3701/FreeCAD-Reinforcement

|

![]()

|

|

|

|

SteelColumn

|

Architecture and construction

|

It provides tools for creating complex steel columns assembled from IPE profiles and plates.

|

ebrahimraeyat

|

https://github.com/ebrahimraeyat/momen

|

![]()

|

|

![]()

|

Timber

|

Architecture and construction

|

It provides tools to facilitate the design and modeling of wood-frame and structural walls.

This workbench is no longer developed nor maintained by its author.

|

j-wiedemann

|

https://github.com/j-wiedemann/FreeCAD-Timber

|

![]()

|

![]()

|

![]()

|

Trails

|

Architecture and construction

|

It provides functionality specific to transportation engineering (roads and rail).

It includes components to perform analysis of curvature.

|

joelgraff

|

https://github.com/joelgraff/freecad.trails

|

![]()

|

|

![]()

|

Wood Frame

|

Architecture and construction

|

It provides tools to facilitate the design and modelling of wood-frame and structural walls, as well as cut lists for beams.

|

JeromeL63

|

https://github.com/JeromeL63/Wood-Frame

|

|

![]()

|

![]()

|

A2plus

|

Assembly

|

It provides tools to create multi-part assemblies.

It is a fork and extension of the older Assembly2 Workbench, but it is not compatible with it.

|

kbwbe

|

https://github.com/kbwbe/A2plus

|

![]()

|

|

![]()

|

Assembly2

|

Assembly

|

It provides tools to create multi-part assemblies.

It is unmaintained since 2016.

Consider using A2plus instead.

|

hamish2014

|

https://github.com/hamish2014/FreeCAD_assembly2

|

![]()

|

![]()

|

![]()

|

Assembly3

|

Assembly

|

It is used to perform assembly of different bodies contained in a single file or in multiple documents.

It was a testbed for the App Link object that was eventually included in the master code.

It is the most complex solution and supports things like interactive kinematics.

|

realthunder

|

https://github.com/realthunder/FreeCAD_assembly3

|

|

|

![]()

|

Assembly4

|

Assembly

|

It is a solution based on the enhanced expression engine and the App Link object developed in the branch of Assembly3.

Assembly4 does not work with a proper constraint solver, instead it uses the expression engine to position bodies with respect to Local Coordinate Systems (LCS).

|

Zolko

|

https://github.com/Zolko-123/FreeCAD_Assembly4

|

![]()

|

|

|

|

Autoload

|

Customization

|

It is a small extension that allows you to select the workbenches that should be loaded when you start FreeCAD.

It can be used in combination with other extensions from the same author such as CommandPanel, PieMenu, and ShortCuts.

|

triplus

|

https://github.com/triplus/Autoload

|

![]()

|

|

|

|

CommandPanel

|

Customization

|

It is an extension that provides a panel that can be used store tools from different workbenches.

|

triplus

|

https://github.com/triplus/CommandPanel

|

![]()

|

|

|

|

CubeMenu

|

Customization

|

CubeMenu provides the ability to manage the FreeCAD navigation cube menu structure and overall appearance.

|

triplus

|

https://github.com/triplus/CubeMenu

|

![]()

|

|

|

|

Glass

|

Customization

|

It is an extension that shows the combo view (tree view and property editor) as a transparent overlay over the 3D view.

|

triplus

|

https://github.com/triplus/Glass

|

![]()

|

|

|

|

IconThemes

|

Customization

|

It is an extension that provides the ability of changing the icons of the default program.

Icon sets aren't provided with this extension; these need to be provided separately.

|

triplus

|

https://github.com/triplus/IconThemes

|

![]()

|

|

|

|

Launcher

|

Customization

|

It is a small extension that provides a dedicated dialog box to search and launch commands.

Instead of clicking on a toolbar button or menu entry, this method of executing commands may be faster for some users.

|

triplus

|

https://github.com/triplus/Launcher

|

![]()

|

|

![]()

|

ModernUI

|

Customization

|

Replaces the standard user interface (UI) with feature such as ribbon menus and collapsing/expanding panels on mouse-over.

|

HakanSeven12

|

https://github.com/HakanSeven12/Modern-UI

|

![]()

|

|

|

|

NavigationIndicator

|

Customization

|

It is an extension that adds an indicator for the mouse navigation style in the status bar.

Since FreeCAD 0.17 this extension is obsolete, as the indicator is included natively in FreeCAD.

|

triplus

|

https://github.com/triplus/NavigationIndicator

|

![]()

|

![]()

|

|

|

PersistentToolbars

|

Customization

|

It is a small extension to keep the toolbars in their locations.

Since FreeCAD 0.17 this extension is obsolete, as the functionality is included natively in FreeCAD.

|

triplus

|

https://github.com/triplus/PersistentToolbars

|

![]()

|

![]()

|

|

|

PieMenu

|

Customization

|

It is a small extension that shows a pie menu to select tools or commands when the Tab key is pressed.

A pie menu is an interface that appears in Blender and other systems like Android mobile phones to launch commands.

|

triplus

|

https://github.com/triplus/PieMenu

|

![]()

|

|

|

|

Pluginloader

|

Customization

|

It is a small extension that allows the user to install macros, external workbenches, and other extensions in FreeCAD.

Since FreeCAD 0.17 this utility is obsolete, as this functionality is already provided by the Addon Manager.

|

microelly2

|

https://github.com/microelly2/freecad-pluginloader

|

![]()

|

![]()

|

|

|

RemBench

|

Customization

|

It is a small extension that remembers and automatically activates a workbench based on the document tab that is selected.

|

triplus

|

https://github.com/triplus/RemBench

|

![]()

|

|

![]()

|

SearchBar

|

Customization

|

It is an extension that adds a search bar next to the what's this? tool.

The search results include tools, objects and preferences.

Other mods can extend it by registering a result provider.

|

Suzanne Soy

|

https://github.com/SuzanneSoy/SearchBar

|

|

|

|

|

SelectorToolbar

|

Customization

|

It is a small extension that provides a point and click experience for switching workbenches.

|

triplus

|

https://github.com/triplus/SelectorToolbar

|

![]()

|

|

|

|

ShortCuts

|

Customization

|

It is a small extension that provides a manager and overlay for shortcuts.

|

triplus

|

https://github.com/triplus/ShortCuts

|

![]()

|

|

|

|

TabBar

|

Customization

|

It is a small extension that adds a window with tabs in order to select workbenches.

|

triplus

|

https://github.com/triplus/TabBar

|

![]()

|

|

|

|

ToolbarStyle

|

Customization

|

It is a small extension that allows the configuration of toolbars, with icons, text, or both.

|

triplus

|

https://github.com/triplus/ToolbarStyle

|

![]()

|

|

![]()

|

MOOC

|

Education

|

It provides an interactive tutorial to learn about FreeCAD directly inside the program.

It allows you to evaluate your self-learning.

|

rockn

|

https://framagit.org/freecad-france/mooc-workbench

|

![]()

|

|

![]()

|

AirPlaneDesign

|

Engineering

|

It is an experimental workbench to design wings and airplane objects.

|

FredsFactory (a179308)

|

https://github.com/FredsFactory/FreeCAD_AirPlaneDesign

|

![]()

|

|

|

|

FreeCADTools

|

Engineering

|

It contains tools to create metal profiles, square tubing, z profile, palette, rotation, drawing, and more.

|

Siardeni

|

https://github.com/Siardeni/FreeCADTools

|

|

|

![]()

|

GDML

|

Engineering

|

It contains tools to handle the Geometry Definition Markup Language (GDML).

|

KeithSloan

|

https://github.com/KeithSloan/GDML

|

![]()

|

|

![]()

|

GDT

|

Engineering

|

It is a collection of tools to add geometric dimensioning and tolerancing (GDT) labels in 2D and 3D technical drawings.

It implements the standard ISO 16792.

|

juanvanyo

|

https://github.com/juanvanyo/FreeCAD-GDT

|

![]()

|

![]()

|

![]()

|

Glider

|

Engineering

|

It contains tools to design paragliders and kites using the OpenGlider library.

|

booya

|

https://github.com/booya-at/OpenGlider

|

|

|

![]()

|

KicadStepUp

|

Engineering

|

It is aimed at helping both KiCad and FreeCAD users in collaborating with electrical (ECAD) and mechanical (MCAD) design.

With FreeCAD it's possible to design a printed circuit board, and push it to KiCad; alternatively, the board can be designed in KiCad, it can be imported by FreeCAD, it can be edited with the Sketcher Workbench, and pushed back into KiCad.

The 3D model, boards and enclosure, can be exported to VRML with materials properties for use in KiCad or Blender.

|

easyw

|

https://github.com/easyw/kicadStepUpMod

|

![]()

|

|

![]()

|

LCInterlocking

|

Engineering

|

It contains tools to create interlocking parts that can be cut with laser-cutters.

Tabs and hinges can be added, and the sketch can be exported to SVG.

|

execuc

|

https://github.com/execuc/LCInterlocking

|

![]()

|

|

|

|

Maker Workbench

|

Engineering

|

The Maker Workbench is composed of a mechatronic components system and an optic components system.

The user can modify these components to customize their own system.

|

David Muñoz

|

https://github.com/URJCMakerGroup/MakerWorkbench

|

![]()

|

|

![]()

|

OSE 3D Printer

|

Engineering

|

A workbench for designing 3D printers by Open Source Ecology for Distributive Enterprise.

|

G Roques

|

https://github.com/gbroques/ose-3d-printer-workbench

|

![]()

|

|

![]()

|

Pyrate

|

Engineering

|

It is used to design optical lenses.

The project aims to provide an optical raytracer for isotropic, homogeneous anisotropic and inhomogeneous isotropic GRIN media.

|

mess42, joha2

|

https://github.com/mess42/pyrate

|

![]()

|

|

![]()

|

Rocket

|

Engineering

|

It provides tools for model and amateur rocket design.

Users can quickly and easily create rocket components suitable for 3D printing, CNC milling, or laser cutting

|

DavesRocketShop

|

https://github.com/davesrocketshop/Rocket.git

|

![]()

|

|

![]()

|

SheetMetal

|

Engineering

|

It provides tools to design an object made of a folded sheet, such as a metal case or enclosure.

The user starts with a flat sheet, then uses tools to extrude and bend the faces of the object until the desired shape is obtained.

The body may then be unfolded to obtain the required flat material, and to use as input for mills or laser cutting machines.

|

Shai Seger and Ulrich Brammer

|

https://github.com/shaise/FreeCAD_SheetMetal

|

![]()

|

|

![]()

|

Ship

|

Engineering

|

It is used to create structures that are common to ships.

It currently is seeking a maintainer.

|

Jose Luis Cercós Pita

|

https://github.com/FreeCAD/freecad.ship

|

![]()

|

![]()

|

![]()

|

CADExchanger

|

Information and data

|

It is an extension that allows FreeCAD to import and export file formats supported by the commercial "CAD Exchanger" application, such as Rhino 3dm or ACIS sat, and mesh formats like OBJ and STL.

|

yorikvanhavre

|

https://github.com/yorikvanhavre/CADExchanger

|

![]()

|

|

|

|

dxf_library

|

Information and data

|

It installs the DXF Python importer and exporter.

This was required in FreeCAD versions v0.15 and below.

This is not needed anymore when using the built-in DXF importer in v0.16 and above.

This library is still needed if you wish to explicitly use the Python importer, or if you wish to export directly from the 3D model.

Please notice that the built-in importer is faster than the Python importer, but in many cases the Python importer produces better results.

|

yorikvanhavre

|

https://github.com/yorikvanhavre/Draft-dxf-importer

|

![]()

|

|

![]()

|

DynamicData

|

Information and data

|

It is an extension that allows creating container objects to hold custom properties of any type that FreeCAD supports, for example, length or placement.

These custom properties can then be used in mathematical expressions just like other properties in the Sketcher Workbench or Spreadsheet Workbench.

|

mwganson

|

https://github.com/mwganson/DynamicData

|

![]()

|

|

![]()

|

InventorLoader

|

Information and data

|

It is an extension designed to import Autodesk Inventor files.

Currently only Parts (IPT) can be displayed, not assemblies (IAM) nor drawings (IDW).

As Inventor files contain a complete ACIS model representation, SAT and SAB files can also be imported.

Export will not be supported, neither to IPT nor to SAT.

|

jmplonka

|

https://github.com/jmplonka/InventorLoader

|

![]()

|

|

![]()

|

ImportNURBS

|

Information and data

|

A workbench to add support for importing 3dm files using open rhino3dm library Noteː This workbench is still under development

|

keithsloan52

|

https://github.com/KeithSloan/ImportNURBS

|

![]()

|

|

![]()

|

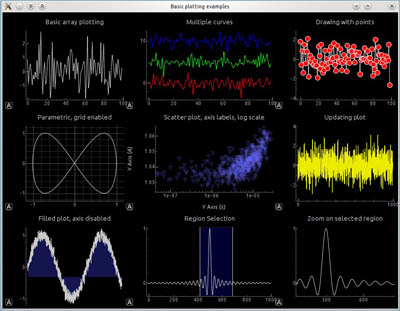

Plot

|

Information and data

|

It is a layer on top of the Matplotlib Python module to graph mathematical functions and vectors of points.

|

Jose Luis Cercós Pita

|

https://github.com/FreeCAD/freecad.plot

|

![]()

|

|

![]()

|

Reporting

|

Information and data

|

It adds tools to extract information from a FreeCAD document using SQL statements, and show the results in a spreadsheet.

The SQL statements can be used from a graphical user interface or from Python scripts.

It works in a similar way to the Arch Schedule tool but is more powerful due to the flexibility that SQL provides.

|

furti

|

https://github.com/furti/FreeCAD-Reporting

|

![]()

|

|

![]()

|

WebTools

|

Information and data

|

It contains a series of tools to communicate with web services like Git, a BIM server, and Sketchfab.

|

yorikvanhavre

|

https://github.com/yorikvanhavre/WebTools

|

![]()

|

|

![]()

|

YAML

|

Information and data

|

It is an extension that adds an importer to load and manipulate objects from YAML files.

In this way it's easier to design and check 3D parts before manufacturing.

|

Mambix

|

https://github.com/Mambix/FreeCAD-yaml-workspace

|

![]()

|

|

|

|

3DfindIT

|

Parts

|

3DfindIT.com, the engineering search engine for 3D components from CADENAS, provides users with easy access to millions of CAD models from thousands of international manufacturers and a range of intuitive search methods.

|

tsielaff, berndhahnebach

|

https://github.com/cadenasgmbh/3dfindit-freecad-integration

|

![]()

|

|

![]()

|

BOLTSFC

|

Parts

|

It is an extension that allows you to use the BOLTS "Open Library for Technical Specifications", which is a collection of objects like nuts, screws, bolts, and so on, parametrically defined.

|

jreinhardt, berndhahnebach

|

https://github.com/berndhahnebach/BOLTSFC

|

![]()

|

|

![]()

|

CadQuery

|

Parts

|

It allows users to design parametric 3D CAD models defined by the CadQuery CAD scripting API.

It includes a full-featured editor with auto-completion, syntax highlighting, line numbering, and code folding.

Example scripts are included.

Script variables can be edited dynamically through the use of a parameter dialog.

This workbench also includes cqparts, which is a library that adds support for parts and assemblies with constraints on top of CadQuery.

|

jmwright

|

https://github.com/jmwright/cadquery-freecad-module

|

![]()

|

|

![]()

|

Fasteners Workbench

|

Parts

|

It is a workbench that provides various fasteners, screws, bolts, nuts, etc., to attach to your model complying with ISO standards.

|

Ulrich Bramar (@ulrich1a) and Shai Seger (@shais)

|

https://github.com/shaise/FreeCAD_FastenersWB

|

![]()

|

|

![]()

|

FCGear

|

Parts

|

It is an extension that adds many different gears like cylindric involute, involute rack, cylindric cycloid, spherical involute bevel-gear, and crown gear.

|

looooo

|

https://github.com/looooo/freecad.gears

|

![]()

|

|

|

|

Frametools

|

Parts

|

It is an extension with tools to create frames and beams, including two intersecting beams, in which one beam is cut by a plane or by another beam.

|

looooo

|

https://github.com/looooo/freecad.frametools

|

![]()

|

|

|

|

Parts Library

|

Parts

|

It is an extension that downloads a library of parts in STEP format .step or in FreeCAD format .FCStd that can be imported into a document.

Users can contribute content to this library by forking the repository, adding their own parts under a permissive CC-BY 3.0 license, and submitting a pull request to merge the new objects.

|

Community

|

https://github.com/FreeCAD/FreeCAD-library

|

![]()

|

|

|

|

PCB

|

Parts

|

It is a workbench that allows the user to import and create printed circuit boards (PCB) in FreeCAD.

It supports layers, colors, transparencies, importing Step and Iges models, and displaying holes and vias.

|

marmni

|

https://github.com/marmni/FreeCAD-PCB

|

![]()

|

|

|

|

Retr3d

|

Parts

|

It is a framework designed to model and manufacture 3D printable parts starting from electronic waste.

The intention of this project is to recycle e-waste, and promote 3D printing, especially in developing economies.

|

Maaphoo

|

https://github.com/Maaphoo/Retr3d

|

![]()

|

|

|

|

Stemfie Workbench

|

Parts

|

It is a workbench that generates a set of parametric parts for the Stemfie Project.

|

Stemfie Community

|

https://github.com/bilbaomakers/StemfieWB

|

|

|

|

|

Symbols Library

|

Parts

|

It is an extension that downloads a library of SVG symbols that can be used in FreeCAD, particularly in the TechDraw Workbench to produce technical documentation.

Users can contribute content to this library by forking the repository, adding their own symbols under a permissive CC-BY 3.0 license, and submitting a pull request to merge the new objects.

|

Community

|

https://github.com/FreeCAD/FreeCAD-symbols

|

![]()

|

|

![]()

|

ThreadProfile

|

Parts

|

It provides tools to create parametric 2D thread profiles compatible with extrusion tools in Part and PartDesign workbenches.

|

mwganson

|

https://github.com/mwganson/ThreadProfile

|

![]()

|

|

|

|

Pivy_trackers

|

Programming

|

Pivy_trackers provides a Python developer with an easy way to directly manipulate the Coin3D scenegraph by generating specific scenegraph node structures which are then inserted and accessed though the pivy_tracker classes.

|

joelgraff

|

https://github.com/joelgraff/pivy_trackers

|

![]()

|

|

![]()

|

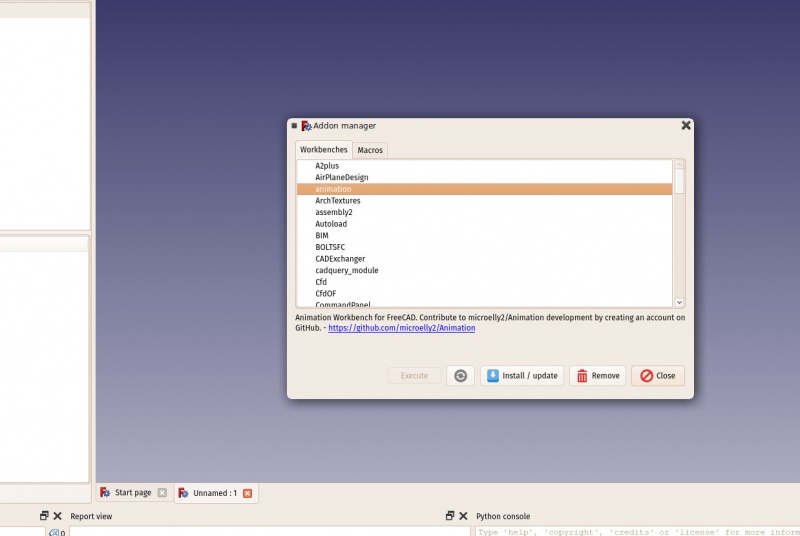

Animation

|

Pseudo-assembly

|

It contains many tools to simulate movement of parts, create sequences of pictures, and thus produce an animation.

The position and rotation of objects can be changed at different times, but also other properties like visibility, transparency, shape color, and camera position.

|

microelly2

|

https://github.com/microelly2/Animation

|

![]()

|

![]()

|

![]()

|

ExplodedAssembly

|

Pseudo-assembly

|

It allows creating exploded views and animations of assemblies.

It was previously known as "ExplodedAnimation".

|

JMG1

|

https://github.com/JMG1/ExplodedAssembly

|

![]()

|

|

![]()

|

Lattice2

|

Pseudo-assembly

|

It provides tools for working with placements and arrays of placements.

It is a sort of assembly workbench but there are no constraints nor relationships.

Instead, the workbench focuses in arrays of placements that can be generated, combined, transformed, superimposed, and populated with shapes.

It can also create exploded assemblies.

|

DeepSOIC

|

https://github.com/DeepSOIC/Lattice2

|

![]()

|

|

![]()

|

Manipulator

|

Pseudo-assembly

|

It is aimed at helping users in aligning, moving, rotating, and measuring 3D objects through a friendly graphical interface.

|

easyw

|

https://github.com/easyw/Manipulator

|

![]()

|

|

![]()

|

Part-o-magic

|

Pseudo-assembly

|

It is an experimental workbench that provides some improvements to Std Part and PartDesign Body containers (automatic grouping, visibility automation, etc.), in order to work with documents that have multiple parts with deep feature hierarchies.

It provides a Body-like container for the Part Workbench, and for other workbenches that produce solid shapes.

Part-o-magic does not provide assembly constraints, but the tools included may be useful in conjunction with a true assembly workbench.

|

DeepSOIC

|

https://github.com/DeepSOIC/Part-o-magic

|

![]()

|

|

![]()

|

Workfeature

|

Pseudo-assembly

|

It provides tools to produce different points, axes, and planes, in order to facilitate the creation of assemblies.

This workbench is based on the older Workfeatures macro, which was hosted in the macros recipes page.

Currently, the macro has a bit more functionality than the workbench, but eventually the workbench will integrate all existing tools of the macro.

They also differ in the graphical user interface; the macro creates a panel next to the tree view and the task panel, while the workbench provides its tools in toolbars, just like other workbenches.

|

Rentlau

|

https://github.com/Rentlau/WorkFeature-WB

|

![]()

|

|

|

|

Kerkythea

|

Rendering

|

It adds a simple exporter to produce XML files for use with the Kerkythea freeware renderer.

|

marmni

|

https://github.com/marmni/FreeCAD-Kerkythea/blob/master/exportToKerkythea.FCMacro

|

![]()

|

|

![]()

|

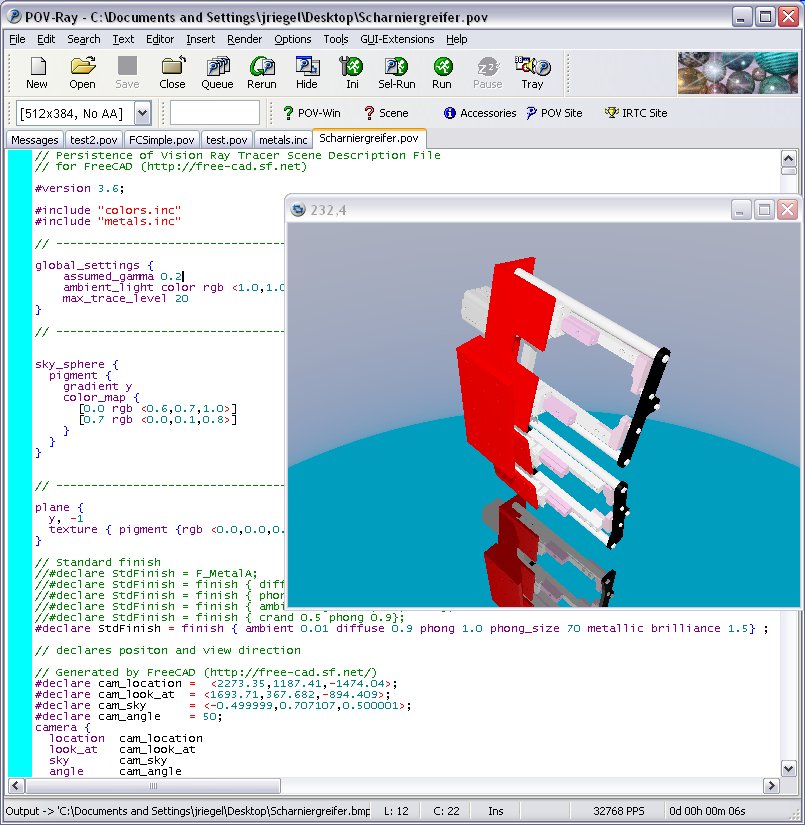

POV-Ray-Rendering

|

Rendering

|

It creates renderings of your FreeCAD model and is very easy to use but also offers all options for advanced users.

|

The_Raytracers

|

https://github.com/TheRaytracers/freecad-povray-render

|

![]()

|

|

![]()

|

Render

|

Rendering

|

It can produce high-quality rendered images, using open-source external rendering engines like Pov-ray, Luxrender, and Appleseed.

Render is a replacement for the Raytracing Workbench, and uses the same templates so they are compatible.

In the future Render may also support Kerkythea, Blender's EEVEE, and OpenCascade's CadRays engines.

|

yorikvanhavre

|

https://github.com/FreeCAD/FreeCAD-render

|

![]()

|

|

![]()

|

3D Printing Tools

|

Shapes

|

It has tools to do small changes to meshes imported from external files like STL.

|

mark1791

|

https://github.com/mark1791/3D_Printing_Tools

|

![]()

|

|

|

|

Cura Engine

|

Shapes

|

It is an extension that integrates CuraEngine into FreeCAD in order to facilitate gcode generation for 3D printing.

This addon is unmaintained since 2014 and no longer works with recent versions of CuraEngine.

|

cblt2l

|

https://github.com/cblt2l/FreeCAD-CuraEngine-Plugin

|

![]()

|

![]()

|

![]()

|

CurvedShapes

|

Shapes

|

It has tools to create 3D curves from 2D profiles

|

chbergmann

|

https://github.com/chbergmann/CurvedShapesWorkbench

|

![]()

|

|

![]()

|

Curves

|

Shapes

|

It is a collection of tools to create and edit NURBS curves and surfaces.

|

tomate44 (Chris_G)

|

https://github.com/tomate44/CurvesWB

|

![]()

|

|

![]()

|

Defeaturing

|

Shapes

|

It provides tools to edit STEP objects to remove features like holes, faces, and edges, and perform some operations with the simplified objects.

|

easyw

|

https://github.com/easyw/Defeaturing_WB

|

![]()

|

|

![]()

|

Design456

|

Shapes

|

Direct modeling tools for FreeCAD.

|

Mariwan Jalal

|

https://github.com/MariwanJ/Design456

|

![]()

|

|

![]()

|

Drawing Dimensioning

|

Shapes

|

It adds dimensioning and annotation tools to the Drawing Workbench.

It is deprecated since FreeCAD 0.17.

Consider using TechDraw Workbench instead.

|

hamish2014

|

https://github.com/hamish2014/FreeCAD_drawing_dimensioning

|

![]()

|

![]()

|

![]()

|

Lithophane

|

Shapes

|

It is an extension to convert a provided image to a "lithophane" for 3D printing.

A lithophane is an image that can only be seen properly when illuminated from behind.

|

furti

|

https://github.com/furti/FreeCAD-Lithophane

|

![]()

|

|

![]()

|

MeshRemodel

|

Shapes

|

It provides tools to help re-create or re-model imported mesh objects to obtain a solid shape.

The workflow is to create points from the mesh's vertices, and use those to create sketches, which can then be extruded.

|

mwganson

|

https://github.com/mwganson/MeshRemodel

|

![]()

|

|

|

|

Nurbs

|

Shapes

|

It is a collection of scripts for managing freeform surfaces and curves.

|

microelly2

|

https://github.com/microelly2/freecad-nurbs

|

![]()

|

|

![]()

|

Pyramids and Polyhedrons Workbench

|

Shapes

|

It has tools for generating pyramids, regular polyhedra and geodesic speres, fully scalable and usable like regular bodies.

|

eddyverl

|

https://github.com/eddyverl/FreeCAD-Pyramids-and-Polyhedrons

|

|

|

|

|

Reconstruction

|

Shapes

|

It provides utilities to reconstruct models from images.

|

microelly2

|

https://github.com/microelly2/reconstruction

|

![]()

|

![]()

|

![]()

|

Silk

|

Shapes

|

It is a collection of NURBS surface modeling tools focused on low degree and seam continuity.

Silk is the new name of the NURBSlib-EVM project.

|

edwardvmills

|

https://github.com/edwardvmills/Silk

|

![]()

|

|

![]()

|

Slic3r-tools

|

Shapes

|

It allows exporting parts, and opening the resulting STL in Slic3r.

You can set up a default print profile, and directly get information about the resources that would be used to 3D print it, as well as quickly generate the .gcode file.

|

limikael

|

https://github.com/limikael/freecad-slic3r-tools

|

![]()

|

|

|

|

SlopedPlanesMacro

|

Shapes

|

It allows you to build figures controlling the slopes of the faces of objects.

|

Damian Caceres Moreno

|

https://github.com/luzpaz/SlopedPlanesMacro

|

![]()

|

|

![]()

|

Cfd

|

Simulation

|

It provides a graphical interface to the OpenFOAM solver to perform computational fluid dynamics (CFD) simulations.

|

qingfengxia

|

https://github.com/qingfengxia/Cfd

|

![]()

|

|

![]()

|

CfdOF

|

Simulation

|

It is a fork of the Cfd workbench that focuses on ease of use; it is intended for people who are just starting in the world of CFD and OpenFOAM.

|

jaheyns

|

https://github.com/jaheyns/CfdOF

|

![]()

|

|

![]()

|

DesignSPHysics

|

Simulation

|

It provides a graphical user interface to DualSPHysics, a fluid dynamics solver using the smoothed particle hydrodynamics (SPH) model.

|

ndrs92

|

https://github.com/DualSPHysics/DesignSPHysics

|

![]()

|

|

![]()

|

EM

|

Simulation

|

It provides a graphical interface for different solvers by FastFieldSolvers.

At present it supports the 3D magneto-quasistatic impedance solver FastHenry.

Support for the 3D electrostatic capacitance solver FasterCap is ongoing.

|

FastFieldSolvers S.R.L.

|

https://github.com/ediloren/EM-Workbench-for-FreeCAD

|

![]()

|

|

![]()

|

FEM FrontISTR

|

Simulation

|

It provides a graphical interface for FrontISTR, an open-source large-scale parallel FEM program for nonlinear structural analysis.

|

kinagaki

|

https://github.com/FrontISTR/FEM_FrontISTR

|

|

|

FreeCAD is a free, open source parametric 3D modeling application.

It is made primarily to model real-world objects, ranging from small electronic components up to large objects such as buildings and civil engineering projects, with a strong focus on 3D-printable objects.

FreeCAD is free to download, use, distribute and modify, and its source code is open and published under the very permissive LGPL license.

The data you produce with FreeCAD is fully yours, and can be recovered without FreeCAD.

FreeCAD is also fundamentally a social project, as it is developed and maintained by a community of developers and users united by their passion for FreeCAD.

This manual is an experiment, taking a different approach from the official FreeCAD documentation wiki.

The wiki is written collaboratively by dozens of community members.

Like most wikis, it contains huge amounts of information but is somewhat difficult to access and navigate by newcomers.

This makes it an excellent resource for reference, but a less practical tool for learning FreeCAD.

This manual will walk you through much of the information available on the wiki, but we hope the step-by-step approach based on examples and a more unified tone due to a smaller number of authors will make it more suitable for a first contact with FreeCAD.

It will become a companion for the wiki, but not replace it.

This manual is being written for the newest stable version of FreeCAD, version 0.18 (early 2019).

The contents of this manual are published under the Creative Commons 4.0 license, and can be freely used, downloaded, copied, and modified.

The source files for this manual are hosted on this wiki, and on the original github account used to write the first version of this book.

Easier to read HTML, PDF, MOBI and EPUB versions are available on GitBook.

A printed version is being prepared.

FreeCAD is a free, open source parametric 3D modeling application.

It is made primarily to model real-world objects, ranging from small electronic components up to large objects such as buildings and civil engineering projects, with a strong focus on 3D-printable objects.

FreeCAD is free to download, use, distribute and modify, and its source code is open and published under the very permissive LGPL license.

The data you produce with FreeCAD is fully yours, and can be recovered without FreeCAD.

FreeCAD is also fundamentally a social project, as it is developed and maintained by a community of developers and users united by their passion for FreeCAD.

This manual is an experiment, taking a different approach from the official FreeCAD documentation wiki.

The wiki is written collaboratively by dozens of community members.

Like most wikis, it contains huge amounts of information but is somewhat difficult to access and navigate by newcomers.

This makes it an excellent resource for reference, but a less practical tool for learning FreeCAD.

This manual will walk you through much of the information available on the wiki, but we hope the step-by-step approach based on examples and a more unified tone due to a smaller number of authors will make it more suitable for a first contact with FreeCAD.

It will become a companion for the wiki, but not replace it.

This manual is being written for the newest stable version of FreeCAD, version 0.18 (early 2019).

The contents of this manual are published under the Creative Commons 4.0 license, and can be freely used, downloaded, copied, and modified.

The source files for this manual are hosted on this wiki, and on the original github account used to write the first version of this book.

Easier to read HTML, PDF, MOBI and EPUB versions are available on GitBook.

A printed version is being prepared.

You can leave the default path here, or change if you wish:

You can leave the default path here, or change if you wish:

No need to set the PYTHONPATH variable, unless you plan to do some advanced python programming, in which case you probably already know what this is for:

No need to set the PYTHONPATH variable, unless you plan to do some advanced python programming, in which case you probably already know what this is for:

During the installation, a couple of additional components, which are bundled inside the installer, will be installed too:

During the installation, a couple of additional components, which are bundled inside the installer, will be installed too:

That's it, FreeCAD is installed.

You will find it in your start menu.

That's it, FreeCAD is installed.

You will find it in your start menu.

Installing a development version

Packaging FreeCAD and creating an installer takes some time and dedication, so usually development (also called pre-release) versions are provided as .zip (or .7z) archives.

These don't need to be installed; just unpack them and launch FreeCAD by double-clicking the FreeCAD.exe file that you will find inside.

This also allows you to keep both the stable and "unstable" versions together on the same computer.

Installing a development version

Packaging FreeCAD and creating an installer takes some time and dedication, so usually development (also called pre-release) versions are provided as .zip (or .7z) archives.

These don't need to be installed; just unpack them and launch FreeCAD by double-clicking the FreeCAD.exe file that you will find inside.

This also allows you to keep both the stable and "unstable" versions together on the same computer.

Auto-load module: (General category, General tab) Normally, FreeCAD will start by showing you the start page.

You can skip this and begin a FreeCAD session directly in the workbench of your choice, listed under Startup, Auto load module after startup.

Workbenches will be explained in detail in the next chapter.

Create new document at startup: (General category, Document tab) Combined with the Auto-load module option above, if checked this starts FreeCAD ready for work.

Auto-load module: (General category, General tab) Normally, FreeCAD will start by showing you the start page.

You can skip this and begin a FreeCAD session directly in the workbench of your choice, listed under Startup, Auto load module after startup.

Workbenches will be explained in detail in the next chapter.

Create new document at startup: (General category, Document tab) Combined with the Auto-load module option above, if checked this starts FreeCAD ready for work.

Storage options: (General category, Document tab) As with any complex application, FreeCAD likely contains bugs causing it to crash occasionally.

Here you can configure options to help you to recover your work in case of a crash.

Authoring and license: (General category, Document tab) Here you set the values to be used for new files you create.

Consider making your files shareable right from the start, by using a friendlier, copyleft license like Creative Commons.

Redirect internal python messages: (General category, Output window tab) These two options are always good to check, as they will cause messages from the internal python interpreter to show up in the Report View when there's a problem running a python script.

Storage options: (General category, Document tab) As with any complex application, FreeCAD likely contains bugs causing it to crash occasionally.

Here you can configure options to help you to recover your work in case of a crash.

Authoring and license: (General category, Document tab) Here you set the values to be used for new files you create.

Consider making your files shareable right from the start, by using a friendlier, copyleft license like Creative Commons.

Redirect internal python messages: (General category, Output window tab) These two options are always good to check, as they will cause messages from the internal python interpreter to show up in the Report View when there's a problem running a python script.

Units: (General category, Units tab) Here you can set the default units system you wish to use.

Units: (General category, Units tab) Here you can set the default units system you wish to use.

Zoom at cursor: (Display category, 3D tab) If set, zoom operations will be focused at the mouse pointer.

If unset, the center of the current view is the zoom focus.

Invert zoom: (Display category, 3D tab) Inverts the direction of zooming relative to mouse movement.

Zoom at cursor: (Display category, 3D tab) If set, zoom operations will be focused at the mouse pointer.

If unset, the center of the current view is the zoom focus.

Invert zoom: (Display category, 3D tab) Inverts the direction of zooming relative to mouse movement.

If you are using the Ubuntu operating system, some of the addons above are also available as packages on the FreeCAD addons PPA

Read more

More download options

FreeCAD PPA for Ubuntu

FreeCAD addons PPA for Ubuntu

Compile FreeCAD yourself

FreeCAD translations

FreeCAD github page

The FreeCAD addons manager

If you are using the Ubuntu operating system, some of the addons above are also available as packages on the FreeCAD addons PPA

Read more

More download options

FreeCAD PPA for Ubuntu

FreeCAD addons PPA for Ubuntu

Compile FreeCAD yourself

FreeCAD translations

FreeCAD github page

The FreeCAD addons manager

The start center is a convenient "welcome screen", that shows useful information for newcomers, like the latest files you have been working on, what's new in the FreeCAD world, or quick info about the most common Workbenches.

It will also notify you if a new stable version of FreeCAD is available.

After a while, when you are more familiar with FreeCAD, you may have made changes in the preferences so when FreeCAD starts you find yourself directly in one of the Workbenches with a new document open.

Or, simply close the start page tab and create a new document:

The start center is a convenient "welcome screen", that shows useful information for newcomers, like the latest files you have been working on, what's new in the FreeCAD world, or quick info about the most common Workbenches.

It will also notify you if a new stable version of FreeCAD is available.

After a while, when you are more familiar with FreeCAD, you may have made changes in the preferences so when FreeCAD starts you find yourself directly in one of the Workbenches with a new document open.

Or, simply close the start page tab and create a new document:

The Workbenches often confuse new users, since it's not always easy to know in which Workbench to look for a specific tool.

But they are quick to learn, and after a short while it will feel natural -- realizing it is a convenient way to organize the multitude of tools FreeCAD has to offer.

Workbenches are also fully customizable (see below).

The same tool may appear in more than one workbench.

The button icon for a particular tool will always be the same no matter which workbench it appears in.

Later in this manual, you will also find a table showing the contents of all Workbenches.

The Workbenches often confuse new users, since it's not always easy to know in which Workbench to look for a specific tool.

But they are quick to learn, and after a short while it will feel natural -- realizing it is a convenient way to organize the multitude of tools FreeCAD has to offer.

Workbenches are also fully customizable (see below).

The same tool may appear in more than one workbench.

The button icon for a particular tool will always be the same no matter which workbench it appears in.

Later in this manual, you will also find a table showing the contents of all Workbenches.

The 3D view is the main component of the interface; it is where the objects you are working with are drawn and manipulated.

You may have several views of the same document (or same objects), or several documents open at the same time.

Each of these views may be individually undocked from the main window.

You may select objects or parts of objects by clicking them, and you can pan, zoom and rotate the view with the mouse buttons.

This will be explained further in the next chapter.

In addition to the 3D view panel, the following information panels are available.

They may be made visible or hidden by selecting them from View → Panels .

The name of the panel appears in the upper left corner of the panel when it is displayed:

The combo view has two tabs:

The Model tab shows you the contents and structure of your document above and the properties (or parameters) of the selected object(s) below.

These properties are separated into two categories:

Data (properties which concern the geometry itself)

View (properties that affect how the geometry looks on screen).

The Tasks tab is where FreeCAD will prompt you for values specific to the workbench and tool you are currently using.

For example, entering a 'length' value when the Draft Workbench Line Tool is being used.

It will clear and switch back to the Model tab after the OK (or Cancel) button is pressed.

Double-clicking the related object in the Model tab will usually reopen the corresponding Task tab in order to modify the settings.

The Tasks tab sometimes has puzzling and frustrating side-effects.

If the Task tab is not empty, some FreeCAD operations will not work as expected.

For example, if you have a single object in your model such as a cube, double-clicking on it will open the Tasks tab to allow you to modify the parameters characterizing the cube.

If you have the Selection view open, you will see the cube's internal name listed there.

The entire cube will turn green in the 3D panel, indicating the entire cube is selected.

Clicking on the background will deselect the entire cube and clear the Selection view.

So far, this is normal behavior.

However, if you now click on a face of the cube, instead of that face being selected, nothing will be selected — because the Tasks tab has not been completed.

Even if you have made no modifications to the parameters there, FreeCAD is waiting for the OK (or other) button in the Tasks tab to be clicked.

The report view is normally hidden, but it is a good idea to open it as it will list any information, warnings or errors to help you decipher (or debug) what you may have done wrong.

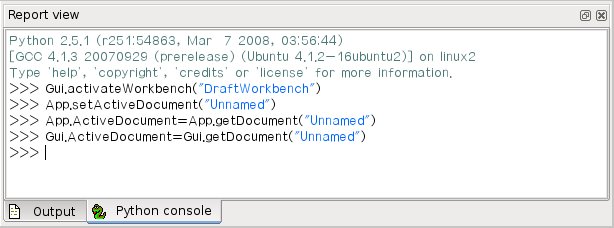

The Python console is also hidden by default.

This is where you can interact with the contents of the document using the Python language.

Since every action you do on the FreeCAD interface actually executes a piece of Python code, having this open allows you to watch the code unfold in real time — allowing you a wonderful and easy way to learn a little Python on the way, almost without noticing it.

The tree view displays only the object tree shown under the Model tab in the combo view.

It is normally hidden.

The property view displays only the object property information shown at the bottom of the combo view.

It is normally hidden.

The selection view shows the names of any objects which are currently selected.

These are the objects to which a workbench operation will be applied.

It can be used to refine the selection by deselecting some of those objects before a workbench operation is applied.

The selection view can also be used to search for objects by name and then select them.

By default, the selection view is hidden.

While you can often determine the currently selected object(s) by looking at the object tree in the Model tab of the combo view, for complex operations requiring multiple selections and where selection is difficult it is helpful to make this view visible so you can both see the labels and count the selected objects.

The 3D view is the main component of the interface; it is where the objects you are working with are drawn and manipulated.

You may have several views of the same document (or same objects), or several documents open at the same time.

Each of these views may be individually undocked from the main window.

You may select objects or parts of objects by clicking them, and you can pan, zoom and rotate the view with the mouse buttons.

This will be explained further in the next chapter.

In addition to the 3D view panel, the following information panels are available.

They may be made visible or hidden by selecting them from View → Panels .

The name of the panel appears in the upper left corner of the panel when it is displayed:

The combo view has two tabs:

The Model tab shows you the contents and structure of your document above and the properties (or parameters) of the selected object(s) below.

These properties are separated into two categories:

Data (properties which concern the geometry itself)

View (properties that affect how the geometry looks on screen).

The Tasks tab is where FreeCAD will prompt you for values specific to the workbench and tool you are currently using.

For example, entering a 'length' value when the Draft Workbench Line Tool is being used.

It will clear and switch back to the Model tab after the OK (or Cancel) button is pressed.

Double-clicking the related object in the Model tab will usually reopen the corresponding Task tab in order to modify the settings.

The Tasks tab sometimes has puzzling and frustrating side-effects.

If the Task tab is not empty, some FreeCAD operations will not work as expected.

For example, if you have a single object in your model such as a cube, double-clicking on it will open the Tasks tab to allow you to modify the parameters characterizing the cube.

If you have the Selection view open, you will see the cube's internal name listed there.

The entire cube will turn green in the 3D panel, indicating the entire cube is selected.

Clicking on the background will deselect the entire cube and clear the Selection view.

So far, this is normal behavior.

However, if you now click on a face of the cube, instead of that face being selected, nothing will be selected — because the Tasks tab has not been completed.

Even if you have made no modifications to the parameters there, FreeCAD is waiting for the OK (or other) button in the Tasks tab to be clicked.

The report view is normally hidden, but it is a good idea to open it as it will list any information, warnings or errors to help you decipher (or debug) what you may have done wrong.

The Python console is also hidden by default.

This is where you can interact with the contents of the document using the Python language.

Since every action you do on the FreeCAD interface actually executes a piece of Python code, having this open allows you to watch the code unfold in real time — allowing you a wonderful and easy way to learn a little Python on the way, almost without noticing it.

The tree view displays only the object tree shown under the Model tab in the combo view.

It is normally hidden.

The property view displays only the object property information shown at the bottom of the combo view.

It is normally hidden.

The selection view shows the names of any objects which are currently selected.

These are the objects to which a workbench operation will be applied.

It can be used to refine the selection by deselecting some of those objects before a workbench operation is applied.

The selection view can also be used to search for objects by name and then select them.

By default, the selection view is hidden.

While you can often determine the currently selected object(s) by looking at the object tree in the Model tab of the combo view, for complex operations requiring multiple selections and where selection is difficult it is helpful to make this view visible so you can both see the labels and count the selected objects.

Read more

Getting started with FreeCAD

Customizing the interface

Workbenches

More about Python

Read more

Getting started with FreeCAD

Customizing the interface

Workbenches

More about Python

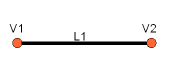

The point where the three axes meet is the origin.

It is the point where the value of all coordinates is zero.

For any given axis, moving in one direction will increase the coordinate value and moving in the opposite direction will decrease the coordinate value.

Every point of every object that exists in the 3D space can be located by its (x,y,z) coordinates.

For example, a point with coordinates (2,3,1) will lie at +2 units on the X axis, +3 units on the Y axis, and +1 unit on the Z axis:

The point where the three axes meet is the origin.

It is the point where the value of all coordinates is zero.

For any given axis, moving in one direction will increase the coordinate value and moving in the opposite direction will decrease the coordinate value.

Every point of every object that exists in the 3D space can be located by its (x,y,z) coordinates.

For example, a point with coordinates (2,3,1) will lie at +2 units on the X axis, +3 units on the Y axis, and +1 unit on the Z axis:

You can look at that scene from any angle, as if you were holding a camera.

That camera can be moved left, right, up and down (pan), rotated around what it is pointing at (rotate) and brought closer to or further from the scene (zoom).

You can look at that scene from any angle, as if you were holding a camera.

That camera can be moved left, right, up and down (pan), rotated around what it is pointing at (rotate) and brought closer to or further from the scene (zoom).

Each of these modes allocates different mouse buttons, or mouse + keyboard combinations, or mouse gestures, to these four operations.

The following table shows the principal available modes:

Each of these modes allocates different mouse buttons, or mouse + keyboard combinations, or mouse gestures, to these four operations.

The following table shows the principal available modes:

or

or

When using the navigation cluster, a control point will turn light blue when the pointer is hovering over a sensitive area.

If the area below the pointer does not change color, clicking on it will have no affect.

As of this writing (v0.18), there are some registration issues which prevent all parts of some control points from being active.

Clicking on a face will switch the view to that face;

clicking on a corner will switch to a view with that corner pointing towards you.

Clicking one of the four triangles will rotate the view 45 degrees in the indicated direction.

Clicking one of the two curved arrows at the top will rotate the view 45 degrees in the indicated direction around a line pointing towards you.

The navigation cluster may be moved to any part of the 3D display by dragging.

The drag (left) mouse button must be pressed inside the cube itself to initiate a drag.

The structure will not begin moving until the pointer is dragged outside the cube.

There is a smaller mini-cube in the lower right of the cluster which activates a drop-down menu allowing you to switch the viewing mode.

When using the navigation cluster, a control point will turn light blue when the pointer is hovering over a sensitive area.

If the area below the pointer does not change color, clicking on it will have no affect.

As of this writing (v0.18), there are some registration issues which prevent all parts of some control points from being active.

Clicking on a face will switch the view to that face;

clicking on a corner will switch to a view with that corner pointing towards you.

Clicking one of the four triangles will rotate the view 45 degrees in the indicated direction.

Clicking one of the two curved arrows at the top will rotate the view 45 degrees in the indicated direction around a line pointing towards you.

The navigation cluster may be moved to any part of the 3D display by dragging.

The drag (left) mouse button must be pressed inside the cube itself to initiate a drag.

The structure will not begin moving until the pointer is dragged outside the cube.

There is a smaller mini-cube in the lower right of the cluster which activates a drop-down menu allowing you to switch the viewing mode.

You can also use the Selection View to select objects by searching for a particular object.

Read more

The FreeCAD navigation modes

Navigation Cluster

You can also use the Selection View to select objects by searching for a particular object.

Read more

The FreeCAD navigation modes

Navigation Cluster

The objects inside a FreeCAD document can be of different types.

Each workbench can add its own types of objects, for example the Mesh Workbench adds mesh objects, the Part Workbench adds Part objects, etc.

If there is at least one document open in FreeCAD, there is always one and only one active document.

That's the document that appears in the current 3D view, the document you are currently working on.

If you switch tabs to another document, that one

becomes the active document.

Most operations always work on the active document.

FreeCAD documents are saved with the .FcStd extension, which is a zip-based compound format, similar to LibreOffice.

If something goes very wrong, it is often possible to unzip it and fix the problem or rescue the data.

Read more

The FreeCAD document

File Format FCStd

The objects inside a FreeCAD document can be of different types.

Each workbench can add its own types of objects, for example the Mesh Workbench adds mesh objects, the Part Workbench adds Part objects, etc.

If there is at least one document open in FreeCAD, there is always one and only one active document.

That's the document that appears in the current 3D view, the document you are currently working on.

If you switch tabs to another document, that one

becomes the active document.

Most operations always work on the active document.

FreeCAD documents are saved with the .FcStd extension, which is a zip-based compound format, similar to LibreOffice.

If something goes very wrong, it is often possible to unzip it and fix the problem or rescue the data.

Read more

The FreeCAD document

File Format FCStd

Two important things are necessary to know:

Recomputation is not always automatic.

Heavy operations, that might modify a big portion of your document, and therefore take some time, are not performed automatically.

Instead, the object (and all the objects that depend on it) will be marked for recomputation (a small blue icon appears on them in the tree view).

You must then press the recompute button (or Edit->Refresh) to have all the marked objects recomputed.

The dependency tree must always flow in the same direction.

Loops are forbidden.

(See DAG, and DAG view) You can have object A which depends on object B which depend on object C.

But you cannot have object A which depends on object B which depends on object A.

That would be a circular dependency.

However, you can have many objects that depend on the same object, for example objects B and C both depend on A.

Menu Tools -> Dependency graph shows you a dependency diagram like on the image above.

It can be useful to detect problems.

Not all objects are parametric in FreeCAD.

Often, the geometry that you import from other files won't contain any parameter, and will be simple, non-parametric objects.

However, these can often be used as a base, or starting point for newly created parametric objects, depending, of course, on what the parametric object requires and the quality of the imported geometry.

All objects, however, parametric or not, will have a couple of basic parameters, such as a Name, which is unique in the document and cannot be edited, a Label, which is a user-defined name that can be edited, and a placement, which holds its position in the 3D space.

Finally, it is worth noting that custom parametric objects are easy to program in python.

Read more

The properties editor

How to program parametric objects

Positioning objects in FreeCAD

Enabling the dependency graph

Two important things are necessary to know:

Recomputation is not always automatic.

Heavy operations, that might modify a big portion of your document, and therefore take some time, are not performed automatically.

Instead, the object (and all the objects that depend on it) will be marked for recomputation (a small blue icon appears on them in the tree view).

You must then press the recompute button (or Edit->Refresh) to have all the marked objects recomputed.

The dependency tree must always flow in the same direction.

Loops are forbidden.

(See DAG, and DAG view) You can have object A which depends on object B which depend on object C.

But you cannot have object A which depends on object B which depends on object A.

That would be a circular dependency.

However, you can have many objects that depend on the same object, for example objects B and C both depend on A.

Menu Tools -> Dependency graph shows you a dependency diagram like on the image above.

It can be useful to detect problems.

Not all objects are parametric in FreeCAD.

Often, the geometry that you import from other files won't contain any parameter, and will be simple, non-parametric objects.

However, these can often be used as a base, or starting point for newly created parametric objects, depending, of course, on what the parametric object requires and the quality of the imported geometry.

All objects, however, parametric or not, will have a couple of basic parameters, such as a Name, which is unique in the document and cannot be edited, a Label, which is a user-defined name that can be edited, and a placement, which holds its position in the 3D space.

Finally, it is worth noting that custom parametric objects are easy to program in python.

Read more

The properties editor

How to program parametric objects

Positioning objects in FreeCAD

Enabling the dependency graph

Read more

All file formats supported by FreeCAD

Working with DXF files in FreeCAD:

Enabling DXF and DWG support

Working with SVG files in FreeCAD

Importing and exporting to IFC

OpenCasCade

Teigha File Converter

IFC Specifications Database

IfcOpenShell

Read more

All file formats supported by FreeCAD

Working with DXF files in FreeCAD:

Enabling DXF and DWG support

Working with SVG files in FreeCAD

Importing and exporting to IFC

OpenCasCade

Teigha File Converter

IFC Specifications Database

IfcOpenShell

Arc 3 points

Arc 3 points Circle 3 points

Circle 3 points Ellipse 3 points

Ellipse 3 points Arc of ellipse

Arc of ellipse Parallel

Parallel Perpendicular

Perpendicular Tangent

Tangent Equal length

Equal length Symmetric

Symmetric Distance

Distance Radius

Radius Internal angle

Internal angle Snell's law

Snell's law Internal alignment

Internal alignment Scaled

Scaled Involute gear wizard

Involute gear wizard New sheet

New sheet View

View Annotation

Annotation Clip

Clip Open browser

Open browser Ortho views

Ortho views Symbol

Symbol Draft view

Draft view Save

Save The difference between the two can be compared to the difference between bitmap and vector images.

As with bitmap images, polygon meshes have their curved surfaces divided into a series of points.

If you look at it closely, or print it very large, you will see not a curved but a faceted surface.

In both vector images and BREP data, the position of any point on a curve is not stored in the geometry but calculated on the fly, with exact precision.

In FreeCAD, all BREP-based geometry is handled by another piece of open source software, OpenCasCade.

The main interface between FreeCAD and the OpenCasCade kernel is the Part Workbench.

Most other workbenches build their functionality on top of the Part Workbench.

Although other workbenches often offer more advanced tools to build and manipulate geometry, since they all actually manipulate Part objects, it is very useful to know how these objects work internally, and be able to use the Part tools since, being more simple, they can very often help you to work around problems that the more intelligent tools fail to solve properly.

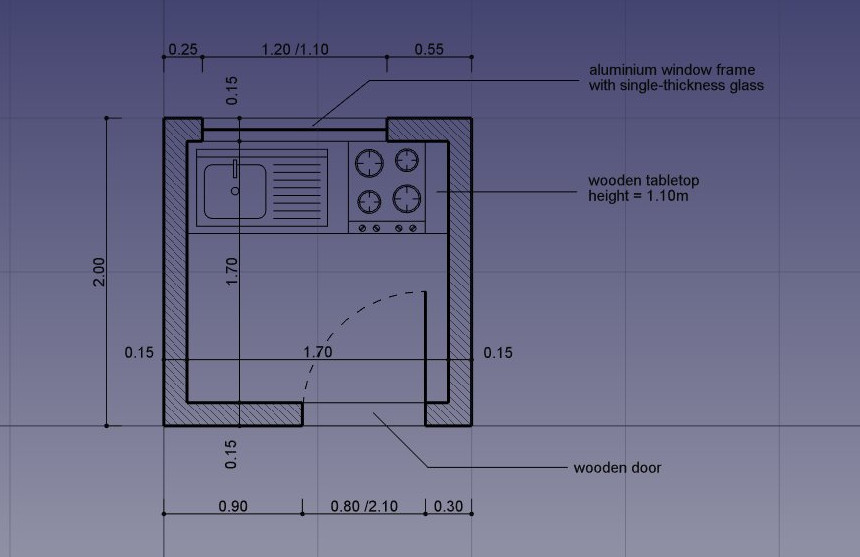

To illustrate the working of the Part Workbench, we will model this table, using only CSG operations (except the screws, for which we will use one of the addons, and the dimensions, which will see in the next chapter):

The difference between the two can be compared to the difference between bitmap and vector images.

As with bitmap images, polygon meshes have their curved surfaces divided into a series of points.

If you look at it closely, or print it very large, you will see not a curved but a faceted surface.

In both vector images and BREP data, the position of any point on a curve is not stored in the geometry but calculated on the fly, with exact precision.

In FreeCAD, all BREP-based geometry is handled by another piece of open source software, OpenCasCade.

The main interface between FreeCAD and the OpenCasCade kernel is the Part Workbench.

Most other workbenches build their functionality on top of the Part Workbench.

Although other workbenches often offer more advanced tools to build and manipulate geometry, since they all actually manipulate Part objects, it is very useful to know how these objects work internally, and be able to use the Part tools since, being more simple, they can very often help you to work around problems that the more intelligent tools fail to solve properly.

To illustrate the working of the Part Workbench, we will model this table, using only CSG operations (except the screws, for which we will use one of the addons, and the dimensions, which will see in the next chapter):

Let's create a new document (Ctrl+N or menu File → New Document) to hold our table design.

The document is initially called "unnamed" in the Model tab in the Combo View panel, but if you save the document (Ctrl+Shift+S or menu File → Save As) as a new FreeCAD document called "table.FCStd" the document will be renamed "table", which more clearly identifies the project.

Now we can switch to the Part Workbench and start to create our first table leg.

Press the

Let's create a new document (Ctrl+N or menu File → New Document) to hold our table design.

The document is initially called "unnamed" in the Model tab in the Combo View panel, but if you save the document (Ctrl+Shift+S or menu File → Save As) as a new FreeCAD document called "table.FCStd" the document will be renamed "table", which more clearly identifies the project.

Now we can switch to the Part Workbench and start to create our first table leg.

Press the

Now we can subtract one from the other: Select the first one, that is, the one that will stay, then, with the CTRL key pressed, select the other one, that will be subtracted (the order is important) and press the

Now we can subtract one from the other: Select the first one, that is, the one that will stay, then, with the CTRL key pressed, select the other one, that will be subtracted (the order is important) and press the

Observe that the newly created object, called "Cut", still contains the two cubes we used as operands.

In fact, the two cubes are still there in the document, they have merely been hidden and grouped under the Cut object in the tree view.

You can still select them by expanding the arrow next to the Cut object, and, if you wish, turn them visible again by right-clicking them or change any of their properties.

You can use Cut -tool and other Boolean tools also through "Combo view" with

Observe that the newly created object, called "Cut", still contains the two cubes we used as operands.

In fact, the two cubes are still there in the document, they have merely been hidden and grouped under the Cut object in the tree view.

You can still select them by expanding the arrow next to the Cut object, and, if you wish, turn them visible again by right-clicking them or change any of their properties.

You can use Cut -tool and other Boolean tools also through "Combo view" with

You might have been thinking that, instead of duplicating the base cube six times, we could have duplicated the complete foot three times.

This is totally true, as always in FreeCAD, there are many ways to achieve a same result.

This is a precious thing to remember, because, as we will advance into more complex objects, some operations might not give the correct result and we often need to try other ways.

We will now make holes for the screws, using the same Cut method.

Since we need 8 holes, two in each foot, we could make 8 objects to be subtracted.

Instead, let's explore other ways and make 4 tubes, that will be reused by two of the feet.

So let's create four tubes by using the

You might have been thinking that, instead of duplicating the base cube six times, we could have duplicated the complete foot three times.

This is totally true, as always in FreeCAD, there are many ways to achieve a same result.

This is a precious thing to remember, because, as we will advance into more complex objects, some operations might not give the correct result and we often need to try other ways.

We will now make holes for the screws, using the same Cut method.

Since we need 8 holes, two in each foot, we could make 8 objects to be subtracted.

Instead, let's explore other ways and make 4 tubes, that will be reused by two of the feet.

So let's create four tubes by using the

You will notice that the cylinders are a bit longer than needed.

This is because, as in all solid-based 3D applications, boolean operations in FreeCAD are sometimes oversensitive to face-on-face situations and might fail.

By doing this, we put ourselves on the safe side.

Now let's do the subtractions.

Select the first foot, then, with CTRL pressed, select one of the tubes that crosses it, press the Cut button.

The hole will be done, and the tube hidden.

Find it in the tree view by expanding the pierced foot.

Select another foot pierced by this hidden tube, then repeat the operation, this time Ctrl+ selecting the tube in the tree view, as it is hidden in the 3D view (you can also make it visible again and select it in the 3D view).

Repeat this for the other feet until each of them has its two holes:

You will notice that the cylinders are a bit longer than needed.

This is because, as in all solid-based 3D applications, boolean operations in FreeCAD are sometimes oversensitive to face-on-face situations and might fail.

By doing this, we put ourselves on the safe side.

Now let's do the subtractions.

Select the first foot, then, with CTRL pressed, select one of the tubes that crosses it, press the Cut button.

The hole will be done, and the tube hidden.

Find it in the tree view by expanding the pierced foot.